Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

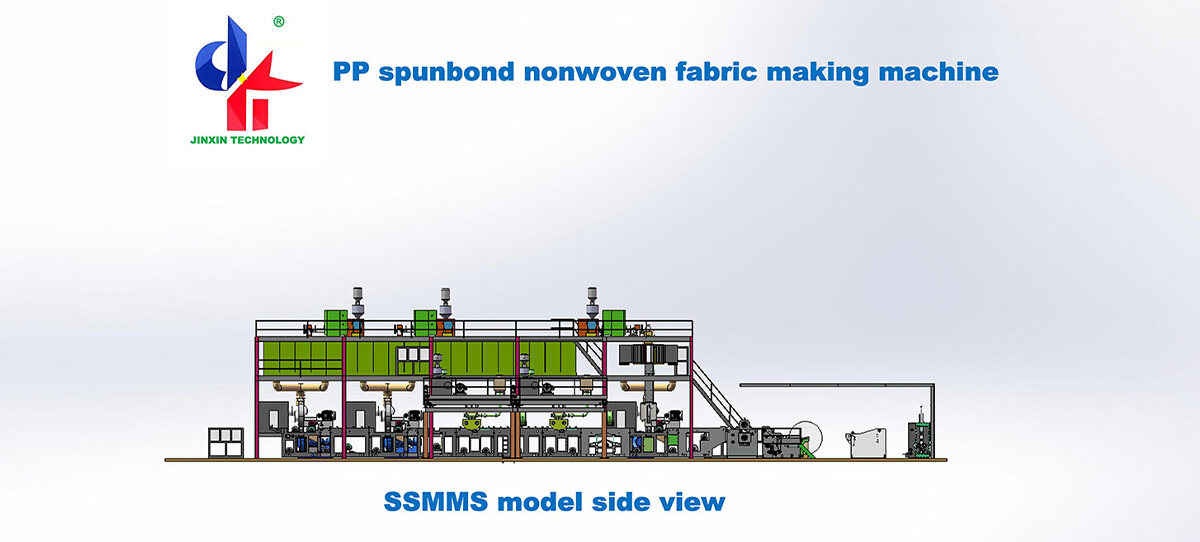

2400mm SSMMS type nonwoven equipment

Its distinctive qualities are reflected in spunbond nonwovens technology. It transcends the distinctions between cloth, film, and paper and has the ability to directly affect the fields of use for all three types of goods. The non-woven fabric machinery uses polypropylene fibre chips as its primary raw material, and it includes a chip conveying device, a melt extrusion spinning system that includes a single screw extruder, a melt pump, a melt filter, a spinning box, a spinneret, and a melt pipe, as well as a cooling and drafting system that includes a side blowing device, a drafting device, a diffusion duct, a vacuum suction device,

| Model | JX-SSMMS |

|---|---|

| Product Width | 2400mm |

| Equipment Size | 60*20*12m |

| Mechanical Speed | 600m/min |

| Gram Weight | 8-120g/m2 |

| Daily Output | 16-25T/Day |

| Transformer Capacity | ≈1600KVA |

| Power Consumption | 1200°-1850°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Non-woven fabric equipment structure

Spunbond Nonwovens Technology reflects its unique features. It breaks the boundaries of cloth, film, and paper, and can directly intervene in the application fields of three types of goods: cloth, film, and paper. The non-woven fabric equipment takes polypropylene fiber chips as the main raw material, and consists of a chip conveying device, melt extrusion spinning system, including a single screw extruder, melt pump, filter, spinning box, spinneret, melt pipe, etc., cooling and drafting system, including side blowing device, drafting device, diffusion duct, vacuum suction device, etc., network forming equipment, hot rolling equipment, slitting and winding equipment, air conditioning and refrigeration system, And an automatic control system.

In recent years, due to the short production process, high production efficiency, excellent product performance, and wide application range, the technology has made significant progress in the process, raw materials, equipment, and products.

The program with logic processing ability and operation processing ability of PLC in non-woven fabric equipment is characterized by adopting modularization, standardization, and other programming methods. When the program is debugged or modified, only the corresponding module needs to be modified, so that it can be read easily and clearly, and more importantly, it is convenient for the debugging process.

A PLC program is the key to the operation of a system, which determines the organic progress of the whole line. In the main interface, the script language is used to realize the function shortcut key. Click the touch panel to switch to the screen of each unit extension, to realize the man-machine dialogue. The production speed of the production line is very fast, and the requirements for synchronous realization are also very high. This feature should be fully considered in the design.

The transmission frequency converter of the wire laying machine and winding machine exchanges data mainly through the data interface of PLC. If we want to achieve a satisfactory dynamic effect, we must realize that digital communication and the lifting speed of the production line are good dynamic effects. To ensure the synchronization function between the wire laying machine and the winder, the winder is also equipped with a tension control system.